-

Time:9/2/2025

-

Time:8/4/2025

-

Time:7/2/2025

-

Time:6/10/2025

-

Time:5/5/2025

- CONTACT US

- [email protected]

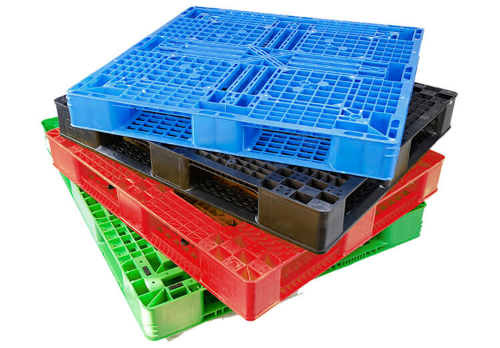

How Much Does a Plastic Pallet Weigh

Time:6/10/2025

Time:6/10/2025 977

977The weight of a plastic pallet varies significantly based on its size, design, load capacity, material composition, and manufacturing process. There is no single standard weight, but here’s a detailed overview of the key factors and typical weight ranges:

Size & Dimensions:

Standard Pallets (48" x 40" / 1200mm x 1000mm): This is the most common size in North America. Plastic versions of this pallet typically weigh between 30 lbs (13.6 kg) and 70 lbs (31.7 kg).

Euro Pallets (1200mm x 800mm): Common in Europe, these usually weigh between 25 lbs (11.3 kg) and 50 lbs (22.7 kg).

Smaller Pallets (e.g., half-pallets, display pallets): Can weigh as little as 10 lbs (4.5 kg) to 25 lbs (11.3 kg).

Larger/Custom Pallets: Designed for heavy machinery or specific industries, these can exceed 100 lbs (45 kg), sometimes reaching 150 lbs (68 kg) or more, especially if reinforced.

Design & Construction:

Solid-Top vs. Grid-Top: Solid tops offer more surface stability but use more plastic, increasing weight. Grid tops are lighter.

Nestable vs. Stackable: Nestable pallets (designed to fit inside each other when empty) are often lighter and thinner, typically in the 20-40 lbs (9-18 kg) range. Stackable pallets need stronger sidewalls and bases, often weighing 40-70 lbs (18-32 kg).

Reinforcement: Pallets designed for very heavy loads (e.g., 2500+ kg dynamic) often incorporate steel rods, metal frames, or thicker ribs, substantially increasing weight into the 60-100+ lbs (27-45+ kg) range.

Runners vs. Block Design: Runner pallets (with longitudinal beams) are generally lighter than block pallets (with blocks supporting all corners and the center).

Material & Thickness:

Material Type: Most are made from HDPE (High-Density Polyethylene) or PP (Polypropylene). HDPE tends to be slightly heavier for the same volume than PP. Virgin material is denser and stronger than recycled, though recycled content is common.

Wall Thickness & Density: The thickness of deck boards, sidewalls, and support structures is the primary driver of weight. Heavy-duty pallets have thick walls and dense ribbing, while lightweight economy pallets minimize material use.

Load Capacity Rating:

Light-Duty (Static ~1000-2000 kg / Dynamic ~500-1000 kg): Weighs 15-30 lbs (7-14 kg).

Medium-Duty (Static ~2500-4000 kg / Dynamic ~1000-1500 kg): Weighs 30-50 lbs (14-23 kg).

Heavy-Duty (Static 5000+ kg / Dynamic 1500-2500+ kg): Weighs 50-80 lbs (23-36 kg).

Ultra Heavy-Duty/Reinforced (Dynamic 3000+ kg): Can weigh 80-150+ lbs (36-68+ kg).

Why Plastic Weight Matters:

Shipping Costs: Especially critical for air freight or when shipping empty pallets back. Lighter pallets reduce fuel consumption and costs.

Material Handling: Workers manually handling pallets benefit significantly from lighter weights (under 50 lbs is often preferred).

Automation Compatibility: Conveyor systems and Automated Guided Vehicles (AGVs) may have weight restrictions.

Total Logistics Cost: While the pallet itself might cost more than wood, the weight savings translate to ongoing freight savings and reduced physical strain.